La prueba de solidez del color en tejidos mediante tarjetas grises es un método de evaluación fundamental y crucial en la industria textil. Su función principal es evaluar objetivamente el grado de cambio de color en los textiles tras someterlos a pruebas como el roce, el lavado, la exposición al sudor y la exposición a la luz, así como el potencial de transferencia de color a tejidos adyacentes.

1. ¿Qué es la solidez del color de los tejidos?

Durante la producción, los tejidos de color, o durante el uso, las prendas confeccionadas con ellos, se ven expuestas a diversos factores ambientales externos. La capacidad de resistir estas fuerzas externas se denomina solidez del color del tejido o la prenda.

2. ¿Qué es la decoloración de la tela?

En los textiles teñidos, los factores ambientales pueden provocar la pérdida de color de la fibra, la destrucción de los cromóforos del tinte o la generación de nuevos cromóforos. Esto conlleva cambios en la saturación, el tono y el brillo del color.

3. ¿Qué es la migración del color en los tejidos?

Esto se refiere al fenómeno por el cual, bajo diversas influencias ambientales, los tintes se desprenden de las fibras originalmente recubiertas y se transfieren a otros tejidos, provocando que se manchen.

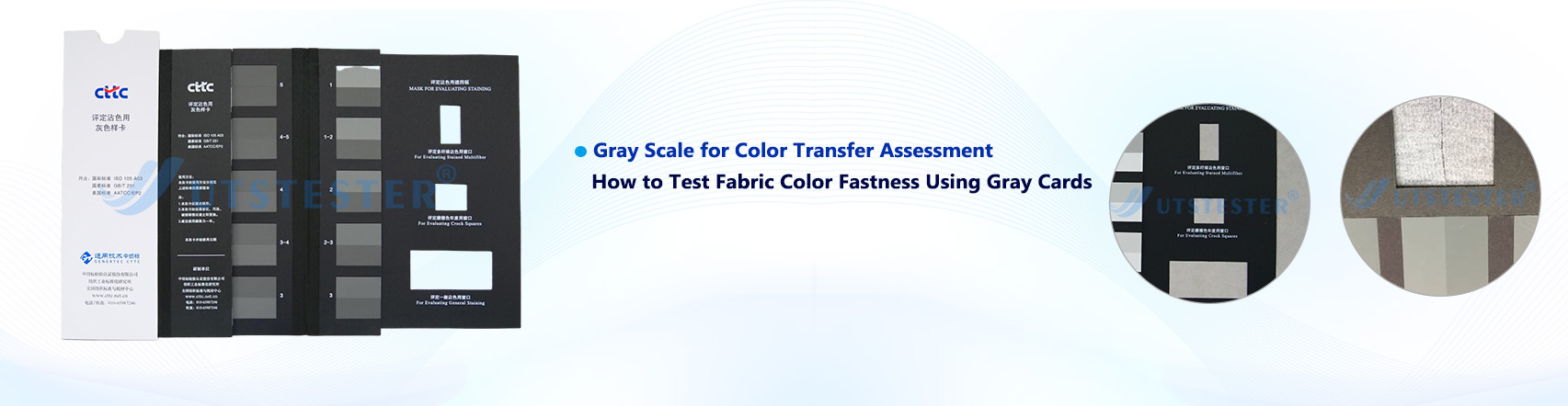

Durante la evaluación de la solidez del color mediante la escala de grises, se utilizan escalas de grises para la decoloración y la migración. Las escalas de grises actualmente utilizadas incluyen las de AATCC, ISO, JIS y la norma nacional china GB. Cada escala de grises presenta niveles de gris ligeramente diferentes.

4. Cómo utilizar la escala de grises para comprobar la solidez del color de los tejidos

4.1 Escala de grises de decoloración: Se utiliza para evaluar los cambios en el color propio de la muestra de ensayo. Consta de 5 pares de pequeñas tarjetas grises, que van del nivel 5 al nivel 1.

El nivel 5 indica que no hay ningún cambio, mientras que el nivel 1 indica el cambio más drástico. En cada par, la tarjeta de la izquierda es de un gris neutro fijo, y la tarjeta de la derecha se aclara gradualmente, representando el grado de cambio de color.

4.2 Tarjetas grises para transferencia de tinte: Se utilizan para evaluar el grado de transferencia de color de la muestra de ensayo a una tela blanca adyacente (comúnmente llamada tela de soporte). Constan de 5 pares de tarjetas pequeñas blancas y grises, que van del nivel 5 al nivel 1.

El nivel 5 indica que no hay transferencia de color, mientras que el nivel 1 indica la transferencia de color más severa. En cada par, la tarjeta de la izquierda es de color blanco fijo y la de la derecha es de un gris progresivamente más oscuro, que representa el grado de transferencia de color.

5. Método de evaluación de la solidez del color en escala de grises

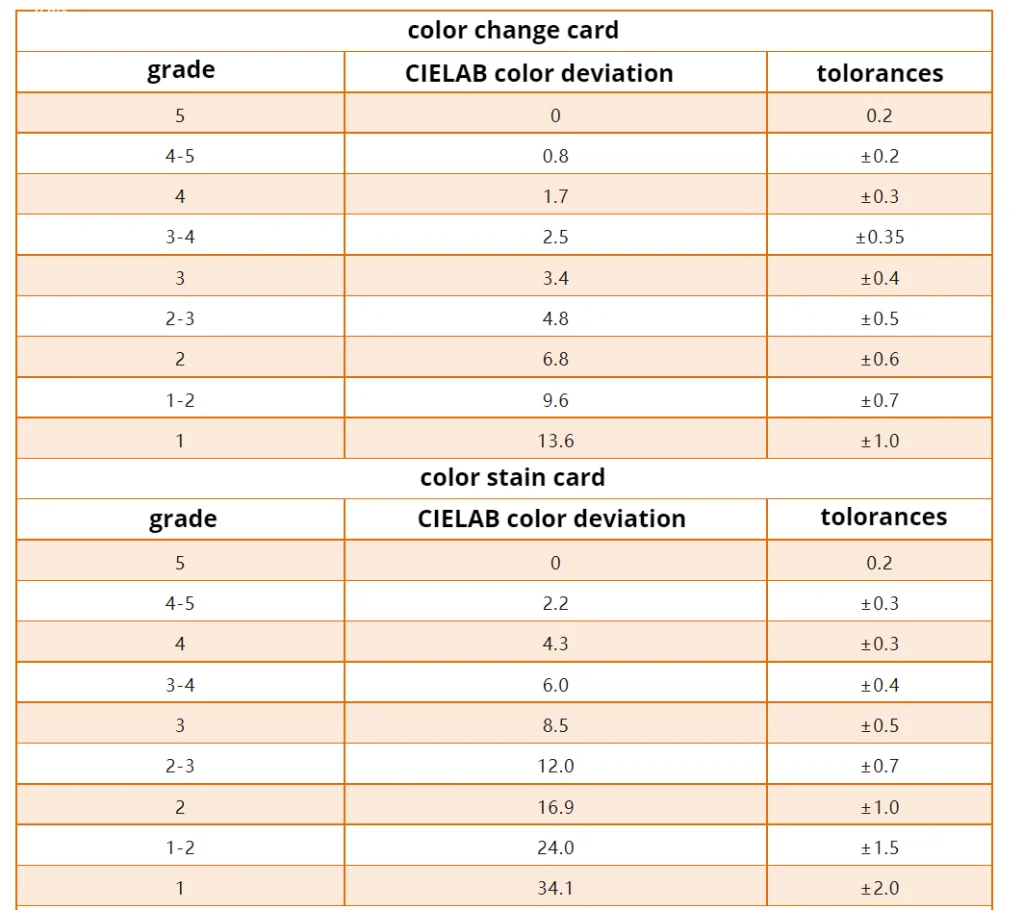

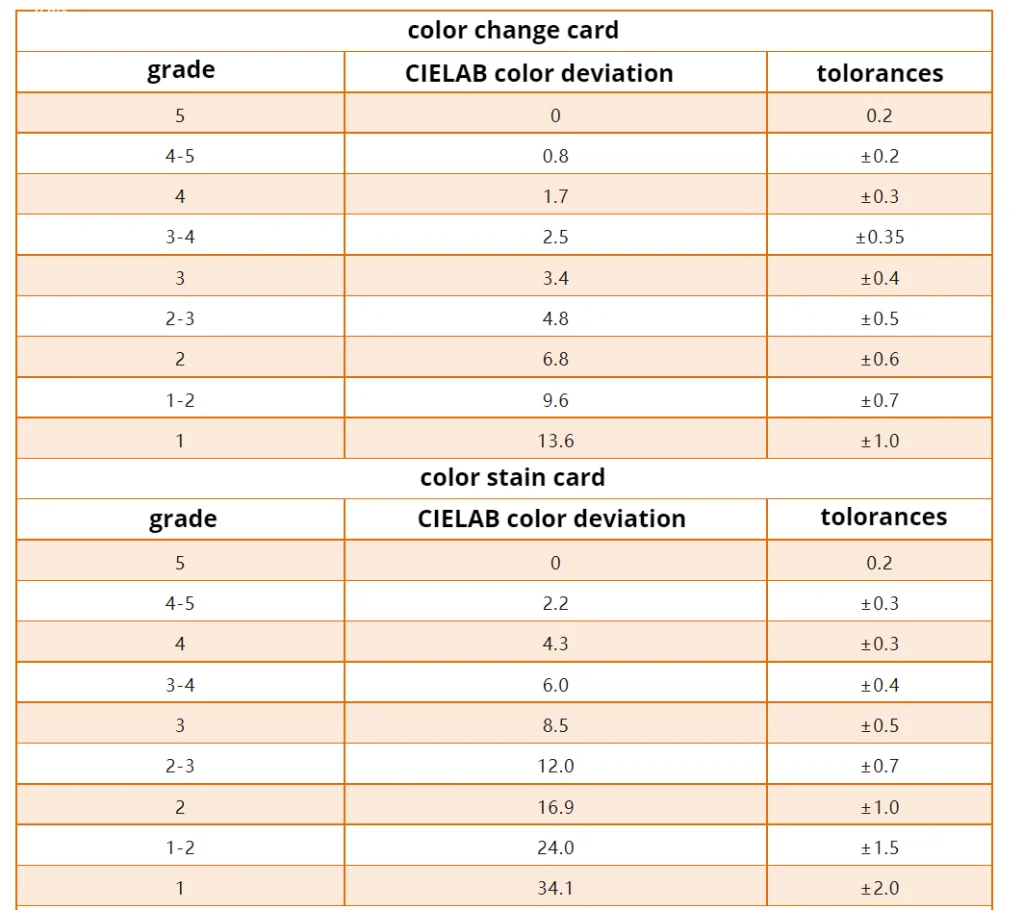

Tabla de escala de calificaciones

Tarjeta de enmascaramiento

(Como se muestra arriba), durante la clasificación, se utilizan aberturas especialmente diseñadas para enmascarar tarjetas de muestra para evaluar la tinción de telas multifibra, la solidez del color al roce y la evaluación general de la tinción.

El uso de tarjetas de enmascaramiento permite centrarse mejor en la muestra que se está calificando, al tiempo que se cubren otras áreas para evitar interferencias visuales.

6. Entorno de calificación

6.1 Fuente de luz

Normalmente utilizamos la fuente de luz D65. Su vida útil es de 2000 horas. También se pueden especificar otras fuentes de luz, como la fuente de luz F, la fuente de luz 84-P, la fuente de luz UV, etc.

6.2 Iluminación de cuarto oscuro

Cuarto oscuro: El proceso de gradación debe realizarse en un cuarto oscuro con humedad y temperatura constantes. Además, las paredes y el mobiliario del cuarto oscuro deben estar pintados de un tono gris neutro, que corresponda aproximadamente al nivel entre el Grado 1 y el Grado 2 de la escala de grises (equivalente a Munsell N5). Como se muestra en la imagen superior, el lado izquierdo muestra el gris neutro de las paredes con las luces encendidas, mientras que el lado derecho muestra el color con las luces apagadas. El cuarto oscuro debe estar completamente libre de cualquier fuente de luz, excepto la de la caja de luz de gradación. Asimismo, no debe haber ningún otro objeto sobre la mesa de gradación.

7. Línea de visión del observador

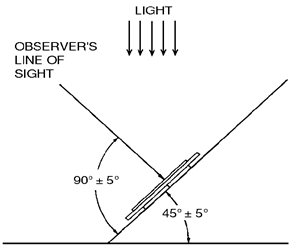

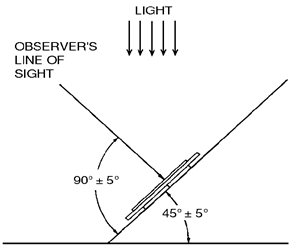

Ángulo de graduación

La clasificación de muestras mediante tarjetas grises requiere ángulos precisos. Esta norma lo exige.

- Muestra colocada a 45° con respecto al plano horizontal

- Graduación de la fuente de luz a 45° con respecto a la muestra

- Los ojos del observador se encuentran a 90° de la muestra

Distancia observador-muestra: 50-70 cm.

8. Precauciones para la visualización de las cabinas de evaluación de la solidez del color

8.1 La fuente de luz es fundamental: La calificación nunca debe realizarse bajo la iluminación interior cotidiana (por ejemplo, lámparas incandescentes o fluorescentes), ya que los resultados se distorsionarán gravemente.

8.2 Ángulo de visión: Durante la observación, la muestra y la tarjeta gris deben colocarse en el mismo plano, con la línea de visión formando aproximadamente un ángulo de 45° con la superficie de la muestra.

8.3 Evaluación por múltiples evaluadores: Para mayor objetividad, dos o más evaluadores deben evaluar las muestras de forma independiente y luego calcular el promedio de las calificaciones. Si las discrepancias superan 0.5 calificaciones, un tercer evaluador debe realizar una reevaluación o se debe llegar a un consenso mediante el diálogo.

Mantenimiento de la escala de grises: Las escalas de grises son instrumentos de precisión. Evite ensuciarlas, rayarlas y exponerlas a la luz. Guárdelas en fundas protectoras después de usarlas.

La clasificación en escala de grises representa la presentación final de los resultados de las pruebas de solidez del color y constituye el paso final en dichas pruebas. Independientemente de la precisión y estandarización del proceso previo, los errores en la clasificación pueden invalidar toda la prueba. La clasificación sigue siendo una tarea compleja. Es fundamental garantizar la coherencia entre el personal de un mismo laboratorio, así como entre las distintas instituciones que realizan las pruebas. A medida que más marcas colaboran con varios laboratorios, la coherencia interlaboratorios se vuelve cada vez más importante.

Correo electrónico:

hello@utstesters.com

Directo: +86 152 6060 5085

Teléfono: +86-596-7686689

Web:

www.uttesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085