Wipes, masks, diapers, and flushable wipes used daily in life may all originate from one material—nonwoven fabric. Nonwoven fabric is a textile that does not require weaving; it is formed by directly bonding fibers together, resulting in a material that is both soft and strong. However, behind this convenience lie issues: low-quality wipes are prone to tearing, certain “flushable” products can clog pipes, and some even contain harmful substances.

To address this, EDANA (European and Asian Nonwovens Association) and INDA (Industrial and Decorative Nonwovens Association) established stringent quality standards—the NWSP (Nonwoven Standard Performance) specifications. These standards specifically target various nonwoven fabrics, evaluating properties such as strength, flushability, and harmful substances. They safeguard our selection of safe and reliable products, ensuring technology truly serves a better life.

NWSP Nonwoven Standard Test Methods Compendium

NWSP 10.1 Three Standard Test Methods for Nonwoven Absorption

Three Standard Test Methods for Nonwoven Absorption Performance

NWSP 10.1 evaluates nonwoven fabrics' liquid absorption rate, liquid absorption capacity, and liquid wicking rate.

NWSP 10.2 Absorption, Rate-Water

Absorption Performance Test - Water Absorption Rate

NWSP 10.2 Absorption Rate Test Method is a standardized technique for quantifying the water absorption rate of wiping materials.

During testing, a set of wiping materials with known mass and dimensions is laid flat on a thermostatically controlled water surface. The time required for complete wetting by the liquid is observed.

Combined with the weight change of the wiping material after wetting, the absorption rate per unit time is calculated by determining the liquid absorption through the material surface.

This method effectively evaluates the rapid water absorption capability of wiping materials in practical applications.

NWSP 10.4 Absorption, Capacity-Oil

Absorption Performance Test - Oil Absorption Capacity

NWSP 10.4 assesses the performance of nonwoven materials in absorbing oils and other fatty liquids. It primarily focuses on two metrics: liquid absorption time and liquid absorption capacity.

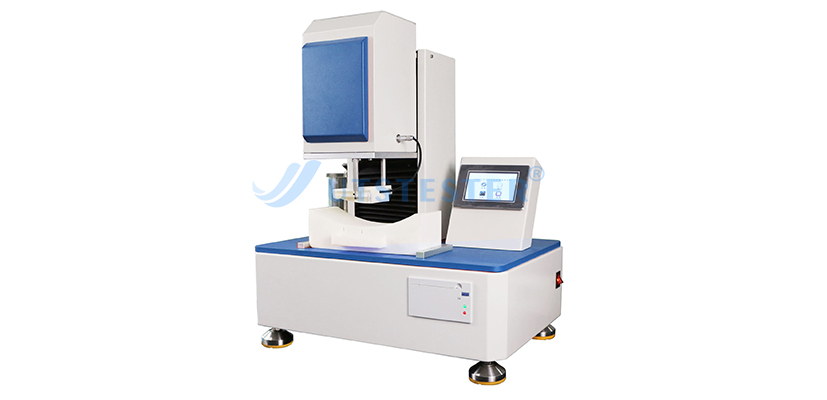

NWSP 20.5 Abrasion Resistance, Martindale

Abrasion Resistance Test - Martindale Method

The NWSP 20.5 abrasion resistance test method evaluates the wear resistance of nonwoven materials during friction. Testing is conducted using a Martindale abrasion tester. This method is applicable to various types of nonwoven materials and can be widely used to compare the durability performance of different materials under long-term use or repeated friction conditions.

NWSP 40.2 Electrostatic Decay

Electrostatic Decay Test

The NWSP 40.2 Electrostatic Decay Test evaluates a material's electrostatic dissipation properties. This method determines the electrostatic characteristics of films or sheet-like nonwovens by measuring the time required for charge to dissipate from the material's surface. This test aids in understanding the material's safety and suitability for electrostatic-sensitive environments.

NWSP 70.1 Air Permeability

Air Permeability Test

The NWSP 70.1 air permeability test method measures the air permeability of nonwoven materials, serving as a key means to evaluate a fabric's airflow capacity. This method applies to various fabric types, including nonwovens, woven fabrics, knits, airbag materials, blankets, brushed fabrics, layered structures, and pile fabrics.

NWSP 70.3 Liquid Strike-Through

Liquid Penetration Test

The NWSP 70.3 liquid penetration test method measures the time required for liquid to penetrate nonwoven cover materials. A specified volume of simulated urine is applied to the sample surface, and the time taken for penetration to the underlying absorbent pad is recorded.

NWSP 70.8 Liquid Strike-Through, Wetback with Repeated Strike-Through

Liquid Penetration and Wetback Test (Multiple Penetration)

The NWSP 70.8 liquid penetration test method evaluates a diaper's top layer's ability to prevent liquid wetback to the skin. Primarily used for quality control, it compares wetback performance among different nonwoven top layer materials or processing techniques.

NWSP 70.9 Rate of Acquisition and Re-Wet

Absorption Rate and Re-Wet Test

The NWSP 70.9 test method evaluates the absorption and retention of 0.9% saline solution by incontinence products under simulated load and pressure conditions. The time required to saturate a fixed volume of saline solution reflects the absorption rate.

WSP 70.10 Centrifugal Liquid Retention Capacity

Centrifugal Liquid Retention Capacity Test

The WSP 70.10 centrifugal liquid retention capacity test evaluates how much liquid incontinence products can retain after undergoing centrifugal force. This method is typically performed after the absorption capacity test to further assess the product's liquid retention performance.

NWSP 80.3 Water Penetration, Spray Impact

Water Penetration Test Under Spray Impact

NWSP 80.3 water penetration testing applies to fabrics expected to exhibit waterproof or water-repellent properties. It is not recommended for testing highly porous fabrics susceptible to significant water penetration.

NWSP 80.6 Water Resistance, Hydrostatic Pressure

Water Resistance Test - Hydrostatic Pressure Method

NWSP 80.6 water resistance testing applies to all nonwoven materials intended as liquid penetration barriers. This method evaluates a nonwoven's resistance to water penetration under varying hydrostatic pressures.

NWSP 80.10 Liquid Strike-Through, Wetback

Liquid Penetration and Wetback Test

NWSP 80.10 Outer Layer Wetback Test evaluates the ability of diaper outer layers to prevent moisture from wicking back to the skin surface after liquid penetration. Primarily used for quality control, this method compares differences in wetback performance among various nonwoven outer layer materials and their treatments. Note: This test does not simulate actual product usage conditions.

NWSP 90.1 Stiffness, Cantilever

Stiffness Test - Cantilever Beam Method

NWSP 90.1 Stiffness Test Method is based on the cantilever bending principle under the fabric's own weight, used to evaluate the stiffness properties of nonwoven fabrics. This method measures the bending length and calculates the bending stiffness accordingly. The test is applicable to most types of nonwoven fabrics, whether treated or untreated, including materials that have undergone sizing, coating, or resin treatment.

NWSP 90.3 Softness, Handle-0-Meter

Softness Test - Handle-0-Meter Method

The NWSP 90.3 hardness test method evaluates the hardness or “hand feel” characteristics of nonwoven fabrics. This test posits that “hand feel” results from the combined effect of surface friction resistance and flexural stiffness of the material.

NWSP 100.1 Tearing Strength, Elmendorf

Tear Strength Test - Elmendorf Method

The NWSP 100.1 tear strength test method utilizes an Elmendorf pendulum apparatus to measure the average force required to tear a nonwoven fabric from a pre-cut notch, thereby evaluating the material's resistance to tearing.

NWSP 100.2 Tensile, Trapezoidal Tear

Tear Strength Test - Trapezoidal Method

NWSP 100.2 Tensile Properties Test Method employs a Constant Rate of Extension (CRE) tester to determine the tear strength of nonwoven fabrics using the trapezoidal method.

NWSP 110.1 Tensile, Grab Strength

Tensile Strength Test - Grab Method

NWSP110.1 Tensile Properties Test Method employs a grab strength test procedure to determine the breaking strength and elongation of most nonwoven materials. This method includes dry and wet test procedures and is applicable to nonwovens and felt fabrics. This test method is not recommended for highly stretchable materials.

NWSP 110.4 Tensile, Strip Method - Dry

Tensile Strength Test - Strip Method (Dry)

NWSP 110.4 Strip Tensile Performance Test Method employs a cut strip testing procedure to determine the breaking strength and elongation of most nonwoven materials. This method includes operational procedures for both dry and wet testing.

NWSP 110.4 Tensile, Strip Method - Wet

Tensile Strength Test - Strip Method (Wet)

NWSP 110.4 Strip Tensile Properties Test Method employs a strip cutting procedure to determine the breaking force and elongation of most nonwoven materials, providing specific protocols for both dry and wet testing.

NWSP 110.5 Resistance to Penetration - Ball Burst

Penetration Resistance Test - Ball Burst Method

NWSP 110.5 Ball Burst Test Method is used to determine the puncture resistance of nonwoven fabrics.

NWSP 130.1 Basis Weight

Basis Weight Test

NWSP 130.1 Basis Weight Test Method measures the mass per unit area of nonwoven material samples.

NWSP 160.1 Lint (Gelbo)

Fiber Shedding Test (Gelbo Method)

NWSP 160.1 Lint Test Method evaluates the relative tendency of fabrics to shed particles when subjected to bending and twisting by a particle generator. During testing, a particle counter measures the quantity and particle size of released particles.

WSP 241.2 Absorption, Retention Capacity - Tea Bag Test

Absorption Retention Capacity Test - Tea Bag Method

WSP 241.2 Liquid retention testing evaluates the liquid retention capacity of polyacrylate (PA) superabsorbent powders after centrifugation in salt solutions.

WSP 242.2 Superabsorbent Materials - Absorption Under Pressure

Superabsorbent Materials - Pressure Absorption Test

WSP 242.2 Pressure Absorption Test Method measures the absorption capacity of polyacrylate (PA) superabsorbent powder under specified pressure conditions, where permeability is a critical parameter requiring strict control during testing.

NWSP 350.1 Menstrual Tampons Absorbency - Syngina Method

Menstrual Tampon Absorbency Test - Syngina Method

NWSP 350.1 Menstrual Tampon Absorbency Test Method employs the Syngina apparatus, specifying the test procedure for determining the absorbency performance of menstrual tampons under in vitro conditions.

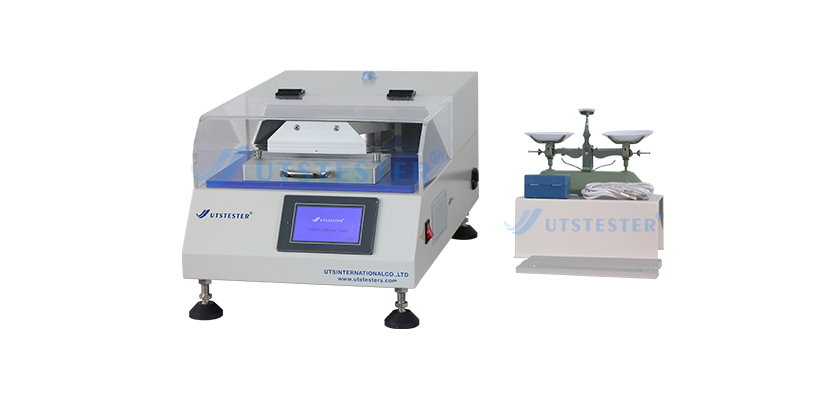

NWSP 402.0 Softness, Cup Crush

Softness Test - Cup Crush Method

NWSP 402.0 Cup Crush testing is an effective method for evaluating material properties during simultaneous multidirectional deformation. This test measures the softness of materials less than 1 mm thick, quantifying flexibility through peak load and energy data.

WSP 511.3 Dispersability, Vortex Method without Screening

Dispersibility Test - Vortex Method without Screening

The WSP 511.3 dispersibility vortex test method evaluates the dispersibility or physical degradability of flushable products during passage through household sewage pumps (e.g., jet pumps and macerator pumps) and municipal sewage conveyance systems (including sewer pipes and lift stations).

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085